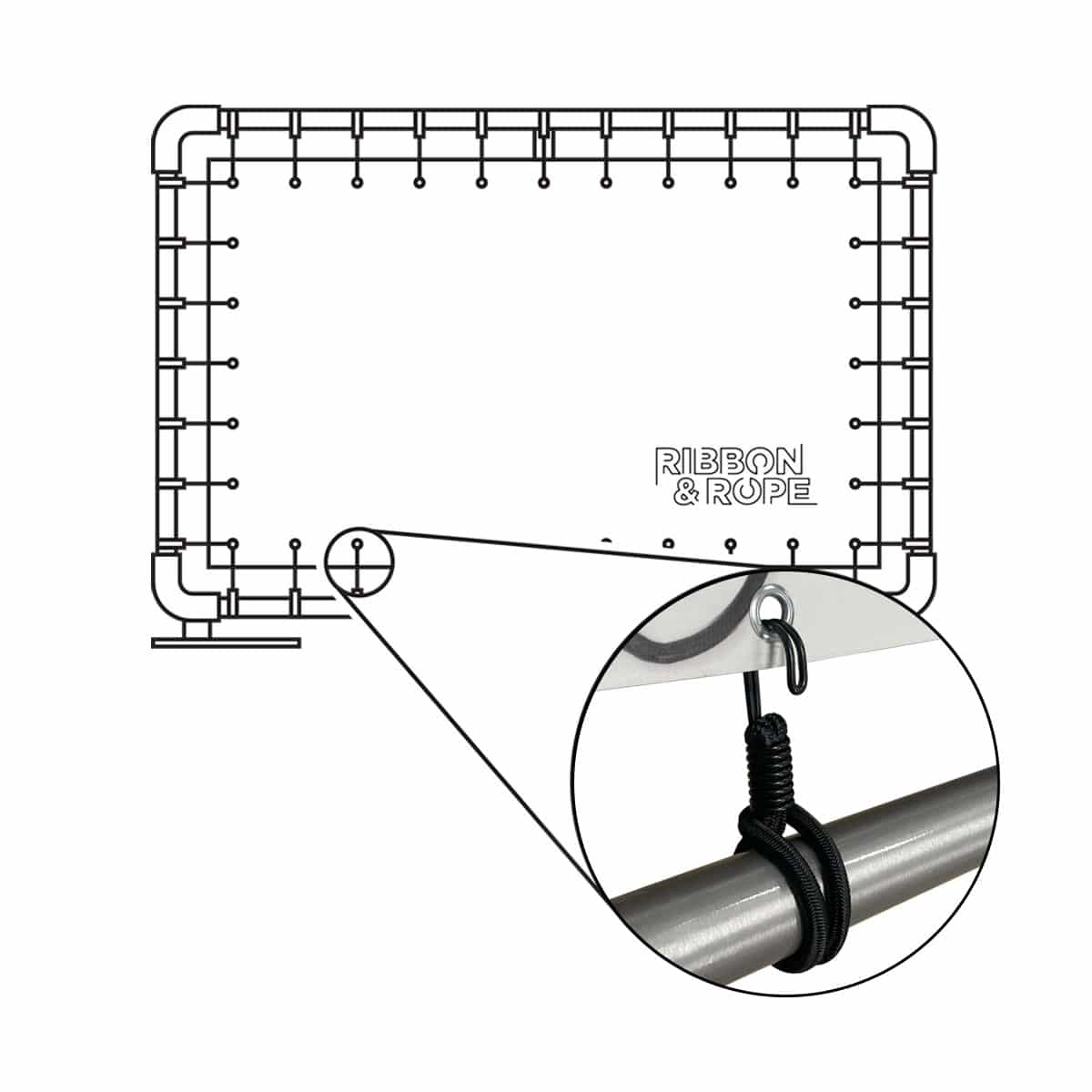

Weldable banner tape with loops

Attach this tape with hot air or an ultrasonic machine to your printed textile without losing print surface. The loops replace the need for using eyelets.

- Trusted by 500+ business partners

- Receive your offer within the same day

- Order directly from stock

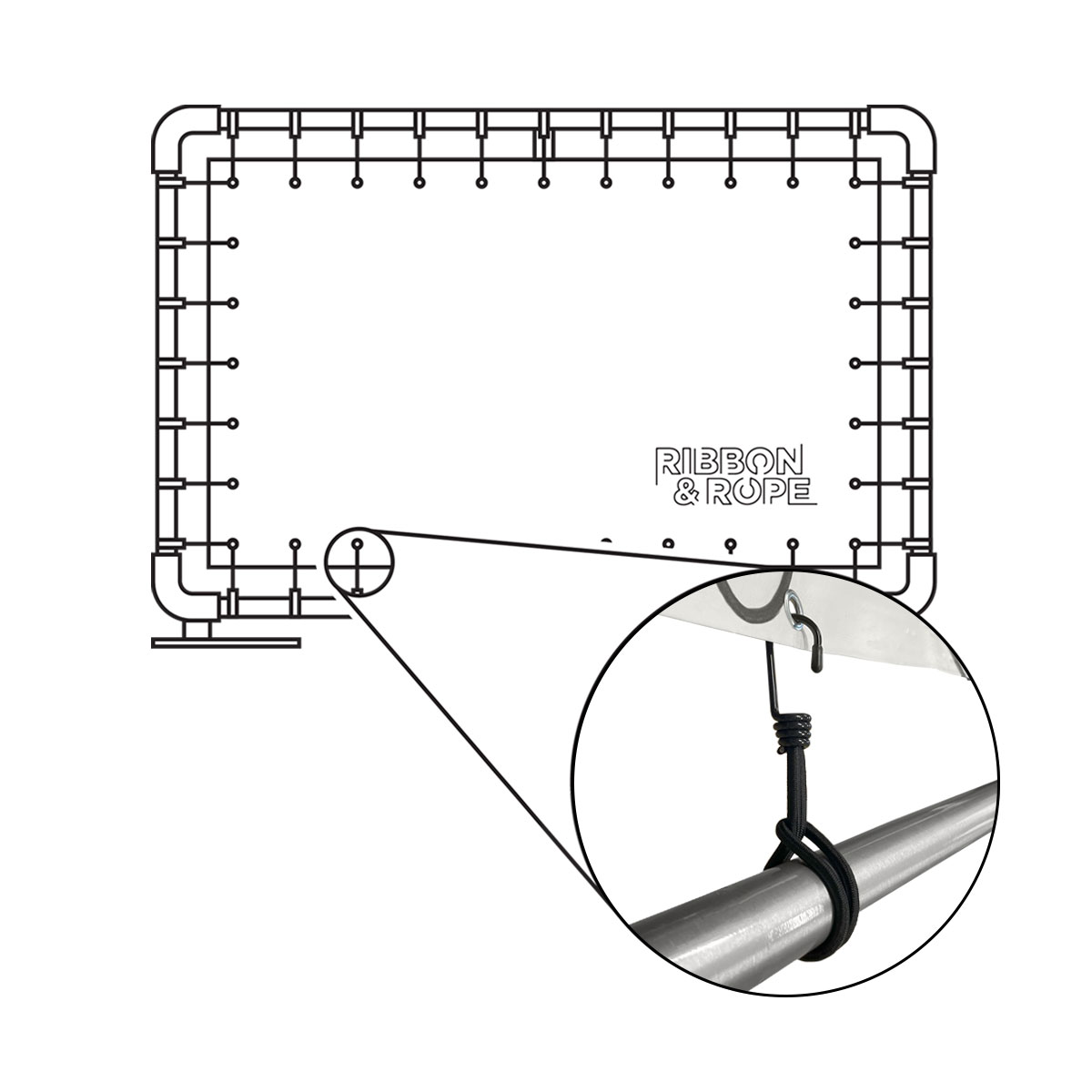

The weldable banner tape with loops is a highly practical and eco-friendly alternative for traditional hemming. Made of polyester material with a PVC coating, this innovative banner tape is easy to attach to the outlines of textile prints using hot air methods. Using this assembly method makes sure that no printed textile surface is wasted. At regular intervals, the tape is equipped with loops, which eliminates the use of separate hems. These integrated loops, ensure a strong and seamless connection, making it ideal for professional banner installations.

Once the printed textile with banner tape has served its purpose, it can be disposed of directly with plastic waste without the need to separate materials. This reduces labour, streamlines recycling, and accelerates sustainability process for the end user.

Please note that for this product a specific storage is obligated, in order to keep the glue at its best state. Ideally, this weldable banner tape should be stored between 5°C and 20°C. Above 30°C the shelf life will be significantly reduced, because of effecting the glue.

- Easy to recycle

- Hot air or ultrasonic attachment

- Strong finish

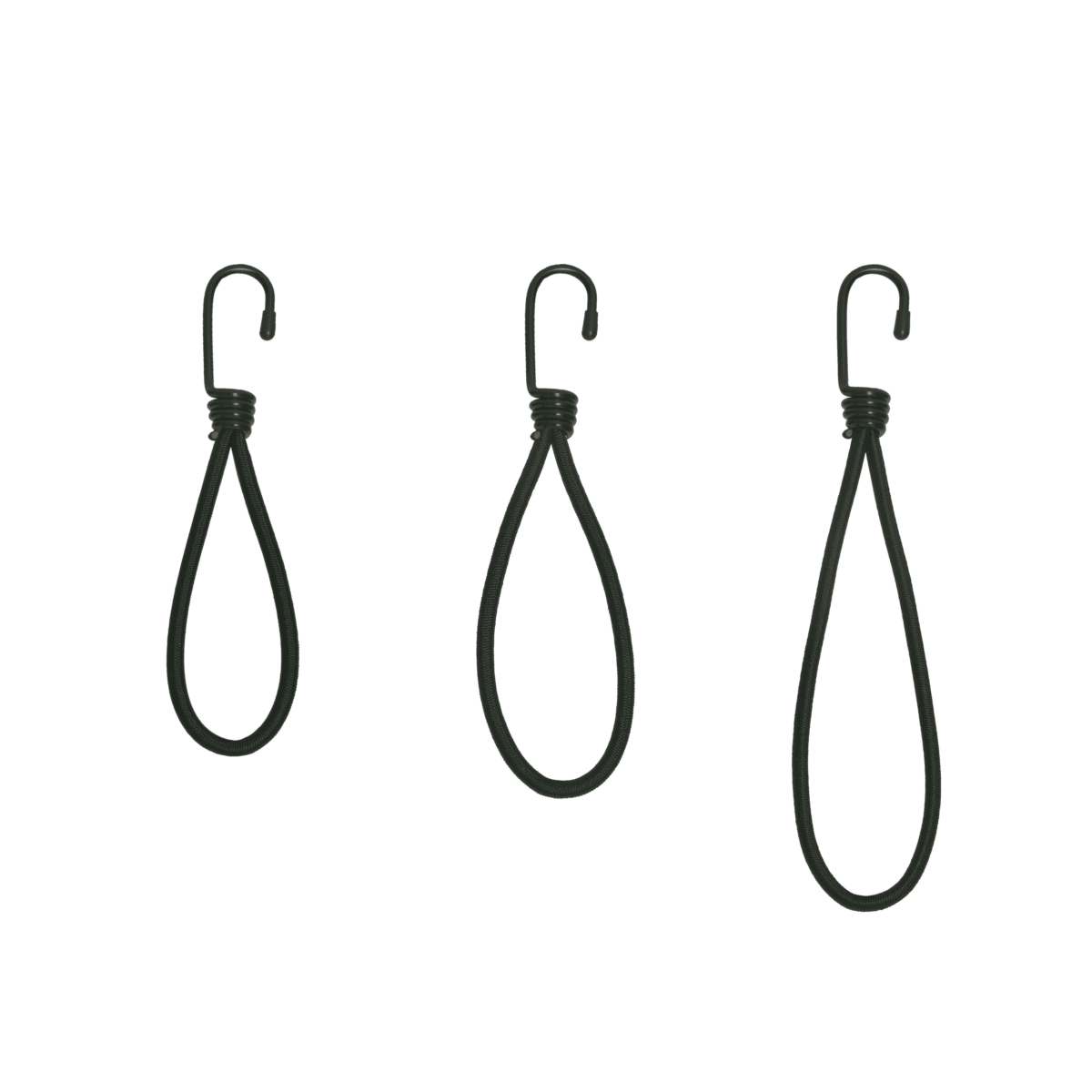

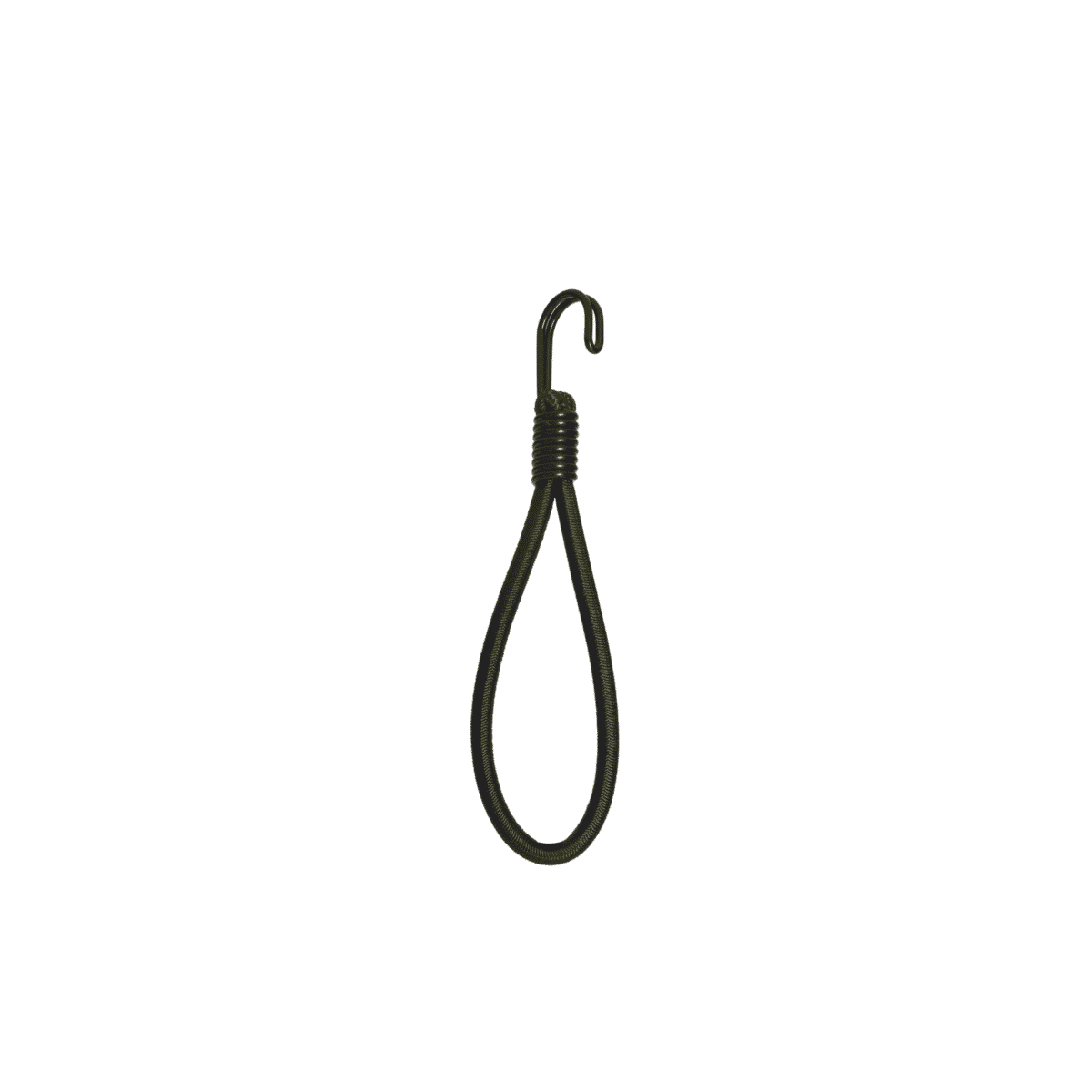

To use the weldable banner tape with loops, position the tape along the edges of your printed textile. Apply the banner tape using high temperatures with hot air or ultrasonic welding machines, to ensure a strong and durable bond. Once secured, attach the printed textile to its frame by threading rope or hooks through the integrated loops on the tape and the frame. This efficient process eliminates the need for hemming while ensuring a reliable and professional finish.